How Do Grounding Electrodes Work?

Grounding electrodes are an important part of any grounding system. They are the method in which the system uses to dissipate fault current into the earth.

How Electrodes Assist Grounding Systems

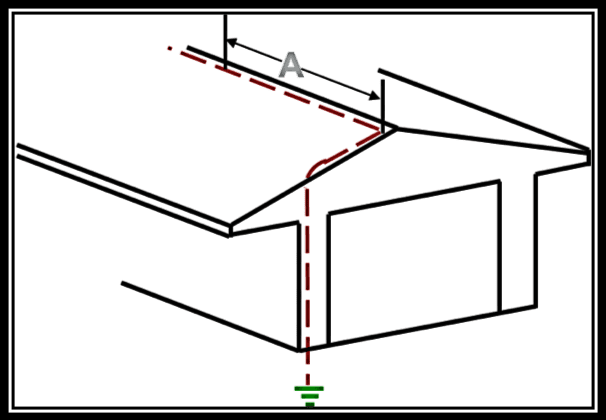

There are two functions of a grounding system that depend heavily on these electrodes. The first and most hazardous is taking the high amperage of a lightning strike off the facility and dissipating it into the earth, (Figure 1). Unlike a typical electrical fault, (where the source of the fault current is the electrical supply and that current will return to that same electrical supply), the fault current from a lightning strike is trying to get to earth in an attempt to equalize the potential between the earth and the sky. By bonding the facility and lightning protection system to multiple grounding electrodes, we provide a low impedance path for this amperage to get to earth.

Figure 1: Lightning Protection Grounding Electrode

The second is to provide a zero-volt reference for the electrical system within the facility. In all residential buildings, the utility transformer and first service disconnect have ground bars that are bonded to grounding electrodes, (Figure 2). The equipment in the building is powered either by a phase to neutral (neutral served load) or phase to phase wiring configuration. In the phase to neutral configuration, the neutral is intended to provide a zero-volt reference for the supply voltage to correct. If the grounding electrode system is subpar, the neutral voltage will be above zero and the voltage difference between neutral and phase will be lower than the equipment’s optimum operating voltage.

Figure 2: Service Entrance Grounding Electrodes

If a grounding electrode system were perfect, it would have zero-ohms resistance to earth. For every ohm or portion thereof, the voltage on the neutral will increase proportionally and the voltage level at the equipment will decrease proportionally.

Grounding Electrode Requirements & Restrictions

There are multiple types of electrodes authorized for use in electrical systems. They are listed in Article 250 of the National Electrical Code. Basically, the code says any grounding electrode listed for use in grounding can be used. However, the code identifies the following along with their installation requirements and restrictions:

- Metallic Cold-Water Pipe (Figure 4) – Must be used if present and must be combined with a supplemental grounding electrode

- In-Ground Building Support Structure (Building Steel) – Must be bonded and can be an electrode if all criteria are met and combined with a supplemental grounding electrode.

- Rod, Pipe, and Plate Electrodes (Figure 3, 5, 6) – Must achieve a 25-ohm or less reading or 2 are required.

- Ground rings (counterpoises) – 20 feet length buried 30 inches deep.

- Concrete Encased (Uffer) Electrodes (Figure 7) – Must be in at least 2 inches of concrete in direct contact with earth.

Figure 3: Driven Grounding Rod

Figure 4: Cold Water Pipe Grounding Electrode

Figure 5: Grounding Plate

Figure 6: Electrolytic (Pipe) Electrode

Figure 7: Concrete Encased Electrode

Each of these electrodes has benefits in specific situations and limitations in other situations, we will be pleased to explain these benefits and limitations in depth. Please contact Support@lyncole.com for further information.